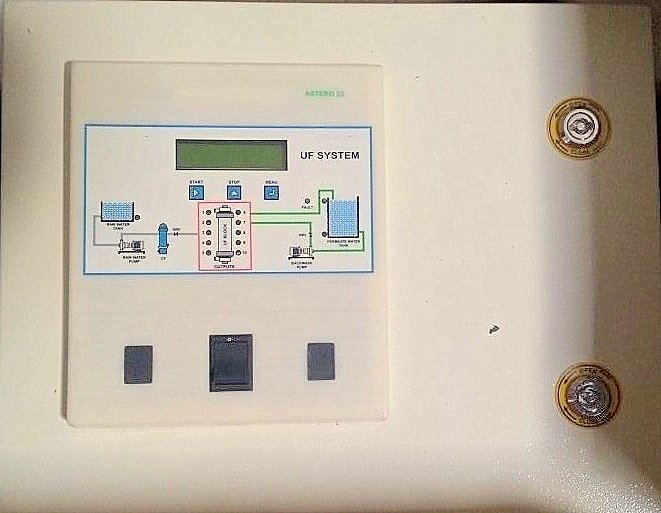

Astero UF NG Panel (4SV)

₹19,500.00

The control panel is designed to operate a UF system automatically.

All the steps happen sequentially after the set timings.

One can configure two counters after any step which would initiate the Step sequence defined.

All step timings are settable at the site For example, one has programmed 3 steps viz Forward Flush, Backwash & Cross Flow & default step is Service. Now we can program the controller in such a way that each service step is followed by a Forward flush. After x number(settable) of such service-forward flush cycles*, the unit will go to backwash step. Further, after y number of backwash cycles unit goes to cross flow step.

One can switch on/off any output in any step(in password 678)*Note: In case the diff.

Pressure input gets energized before the set number of Service-forward flush cycles; the unit will immediately go into backwash.

The panel basically can take 5 inputs namely raw water tank level, treated water tank level & three auxiliary inputs(which can be configured as DPS- differential pressure switch, TWLOL-treated water tank low level, RL2, DOSLVL) and controls 11 outputs viz. Raw water pump, Backwash pump and 8 valves(solenoid/motorized).The advanced electronic also takes care of required motor protection such as Overload, dry running & single phasing.

Reviews

There are no reviews yet.